An unlikely contender in the battle for wildlife conservation has entered the ring: drones.

Thanks to an ability to cover large areas at low costs, drones are playing a part in the reduction of wildlife threats.

Globally, drones aid in everything from migration tracking and nest surveys to habitat management and anti-poaching activities.

Drones are changing wildlife conservation around the world.

Drones and Conservation

Since the 1970s, orangutan numbers have decreased sharply. Currently, the International Union for the Conservation of Nature and Natural Resources (IUCN) lists orangutan's as critically endangered.

Today, orangutans face growing threats from poaching and palm oil production across South Asia. Monitoring these animals is now more important than ever.

Conserving the orangutan population effectively requires producing data that is both accurate and timely. Data includes the density, distribution, and land cover change of these animals.

Collecting such data even once was time-consuming and challenging for rangers to acquire via ground surveys. Now, this task is increasingly more efficient with the aid of UAVs.

Today, the Sumatran Orangutan Conservation Program (SOCP) in Indonesia flies drones above the tree canopy. Drones monitor and track endangered populations by observing nests.

Drones, equipped with video cameras, capture high-resolution images that are often too costly to obtain otherwise. Plus, drones can fly pre-programmed missions autonomously for up to 50 minutes and over a distance of 25 km. This helps researchers survey and map forests as well as their biodiversity.

Catching Poachers

South Africa is home to more rhinoceros than any other country, housing 83% of Africa’s rhinos.

Unfortunately, the country also experiences the highest levels of poaching, which is the primary threat to the conservation of the species.

In recent years, poaching deaths increased significantly. The continent’s elephant population declined by 30% from 2007 to 2014. In 2015, poacher's killed at least 1,338 for their horns, threatening the complete extinction of elephants and rhinoceroses.

Past efforts to stop poaching throughout the country have seen little success—until now.

Backed by funding from the World Wildlife Fund, including $5 million from Google, teams are evaluating their ability to combat poachers.

The Air Shepherd Initiative (ASI) group uses analytics to identify poaching areas. Once areas are identified via the algorithm, drones equipped with night vision are sent to track poachers. Once poachers are spotted, rangers are sent to intercept the invaders.

Flying drones up to 15 miles away at night gives ASI critical advantages.

The majority of poachers know that patrols are less effective after dark. Most poaching occurs at night, leaving the parks highly vulnerable once the sun sets. Night vision equipped drones are changing that disadvantage.

Since the program’s launch, ASI completed over 4,000 missions across 3 countries.

Humpback Whales in Antarctica

Traditionally, biologists and zoologists use helicopters, small planes and satellite photography to learn the migration habits of wild animals. However, these methods take a significant amount of time and resources.

“Drones offer a very safe, green, and inexpensive alternative to manned aircraft,” said David Bird, professor of wildlife biology at McGill University.

Significantly smaller and more affordable, drones still capture detailed photographs needed for these efforts. Also, drones can be fitted with thermal cameras and sensors for more accurate monitoring.

Not only do drones utilize less resources, they’re also safer. According to Bird, small plane and helicopter crashes are leading causes of death for wildlife biologists counting animals or surveying nests.

In Antarctica, marine biologists from Duke University use drones along coastlines and nearby seas to monitor the habits of humpback whales.

The team hopes to learn how many whales work together to feed and if roles vary. And the advantage of observing such behavior from above via drone, versus from a boat or from ashore, are numerous.

KDE Direct recently announced new features for their UAS (unmanned aerial system) UVC electronic speed controller (ESC) series and KDE Device Manager V1.32 software. Upgrades include data logging and graphing, stall protection, and motor control optimizations.

The new data graphing and logging features are accessible by updating the UVC Series ESC to the latest firmware. During a flight, the UVC Series ESC records the following:

KDE Direct recently announced new features for their UAS (unmanned aerial system) UVC electronic speed controller (ESC) series and KDE Device Manager V1.32 software. Upgrades include data logging and graphing, stall protection, and motor control optimizations.

The new data graphing and logging features are accessible by updating the UVC Series ESC to the latest firmware. During a flight, the UVC Series ESC records the following:

An Ingress Protection Rating, or IP rating, is a laboratory-certified industrial rating for a piece of electronic equipment or an enclosure for electrical equipment.

The IP Rating explains the degree of protection provided against debris and water intrusion. It also measures protection against accidental contact -- including body parts like fingers or hands -- to critical components.

Developed by the International Electrotechnical Commission (IEC), this internationally recognized rating system is in wide use in Europe and Asia. North America is adopting this standard at a slower pace.

An Ingress Protection Rating, or IP rating, is a laboratory-certified industrial rating for a piece of electronic equipment or an enclosure for electrical equipment.

The IP Rating explains the degree of protection provided against debris and water intrusion. It also measures protection against accidental contact -- including body parts like fingers or hands -- to critical components.

Developed by the International Electrotechnical Commission (IEC), this internationally recognized rating system is in wide use in Europe and Asia. North America is adopting this standard at a slower pace.

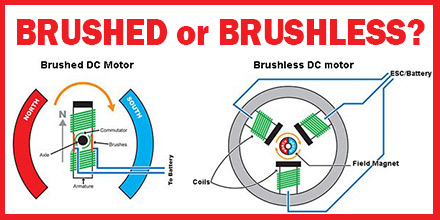

The biggest difference between brushed and brushless motors, unsurprisingly, is the brush. Otherwise, the principle behind the internal workings of brushed and brushless motors are much the same.

As the motor windings energize, it creates a temporary magnetic field to repel or attract permanent magnets. This magnetic force is converted to shaft rotation, allowing the motor to do work.

As the shaft rotates, the electric current is routed to different sets of windings. This maintains electromotive repulsion or attraction, forcing the rotor to continually rotate.

The biggest difference between brushed and brushless motors, unsurprisingly, is the brush. Otherwise, the principle behind the internal workings of brushed and brushless motors are much the same.

As the motor windings energize, it creates a temporary magnetic field to repel or attract permanent magnets. This magnetic force is converted to shaft rotation, allowing the motor to do work.

As the shaft rotates, the electric current is routed to different sets of windings. This maintains electromotive repulsion or attraction, forcing the rotor to continually rotate.

An unlikely contender in the battle for wildlife conservation has entered the ring: drones.

Thanks to an ability to cover large areas at low costs, drones are playing a part in the reduction of wildlife threats.

Globally, drones aid in everything from migration tracking and nest surveys to habitat management and anti-poaching activities.

Drones are changing wildlife conservation around the world.

An unlikely contender in the battle for wildlife conservation has entered the ring: drones.

Thanks to an ability to cover large areas at low costs, drones are playing a part in the reduction of wildlife threats.

Globally, drones aid in everything from migration tracking and nest surveys to habitat management and anti-poaching activities.

Drones are changing wildlife conservation around the world.

To choose the optimal drone propeller blade, the user should consider a number of factors.

Drone propeller blades have a significant influence on power and affect how smoothly a drone flies.

As such, flight efficiency is one of the most important considerations. It begs the question, how will new drone propeller blades improve the flight efficiency of your multi-rotor UAV?

When selecting new drone propeller blades, the following factors are important considerations:

To choose the optimal drone propeller blade, the user should consider a number of factors.

Drone propeller blades have a significant influence on power and affect how smoothly a drone flies.

As such, flight efficiency is one of the most important considerations. It begs the question, how will new drone propeller blades improve the flight efficiency of your multi-rotor UAV?

When selecting new drone propeller blades, the following factors are important considerations:

Although multi-rotor drones get most of the attention in the UAV world today, they’re not the only option for a flight project. But why would someone choose a multi-rotor over a single-rotor...or vice versa? Read on to learn the differences between the two, as well as their strengths and weaknesses.

A key difference between the two, not surprisingly, is the number of rotors each offers. A multi-rotor aerial vehicle has several rotors that keep it airborne. In contrast, a single-rotor vehicle has one rotor plus a tail rotor to control its heading.

Although multi-rotor drones get most of the attention in the UAV world today, they’re not the only option for a flight project. But why would someone choose a multi-rotor over a single-rotor...or vice versa? Read on to learn the differences between the two, as well as their strengths and weaknesses.

A key difference between the two, not surprisingly, is the number of rotors each offers. A multi-rotor aerial vehicle has several rotors that keep it airborne. In contrast, a single-rotor vehicle has one rotor plus a tail rotor to control its heading.