Your challenge, should you choose to accept it…

Your challenge, should you choose to accept it…

You’ve been asked to survey some points on the ground with centimeter-level accuracy. Feeling confident?

How about a few hundred points spread over 7.5 hectares (18.53 acres) and the job has to be done in one afternoon. Throw in the fact that the area you have to survey is in a quarry which has been closed off due to a recent landslide. Still feeling confident?

You should and here’s why.

Improvements in Unmanned Aerial Vehicle (UAV) technology combined with more compact high-end Global Navigation Satellite Systems (GNSS) receivers means that you no longer have to compromise on precision to measure in those hard-to-reach areas.

Before the flight

UAVs have become more reliable and easier to work with: from programming flight paths to installing additional equipment on board, UAV applications are no longer confined to a limited group of specialists.

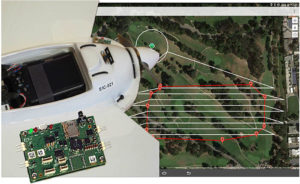

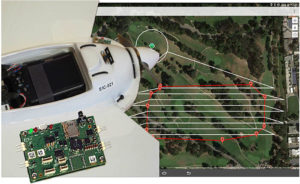

For a survey flight, your UAV will need to have installed: a high-resolution camera and a high-end GNSS receiver module. To fly the UAV through a pre-programmed flight plan, an autopilot flight controller is often included.

The flight

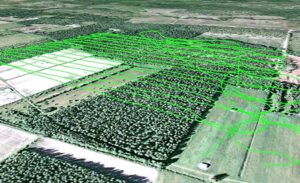

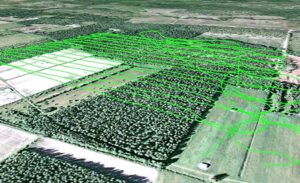

The flight path shown below covered 7.5 hectares (18.53 acres) and was flown in 15 minutes. The 143 photographs taken during the flight were geotagged with GNSS standalone mode positions. Accuracies in standalone mode are typically around 1 to 4 meters (3.28 to 13.13 ft).

If the on-board receiver receives correction information in real time from a nearby GNSS base station, it calculates positions using the more precise (centimeter-level) RTK mode.

With the necessary data from a GNSS base station, RTK positioning can also be calculated ‘offline’ in the processing step using GeoTagZ as described below. Offline reprocessing using GeoTagZ removes the need for a real-time data connection between the UAV and base station which simplifies the hardware setup on the UAV and reduces the payload.

Back in the office: Geotagging

The AsteRx-m UAS receiver recorded the times the photographs were taken by time-stamping a pulse signal from the camera shutter. It also recorded dual-frequency GNSS measurements during the flight.

The GeoTagZ software uses the GNSS data recorded by the receiver and, combining it with the base station reference file, is able to calculate centimeter-level RTK positions for georeferencing the photographs. The EXIF data of the photographs is then replaced with the more accurate RTK georeferences ready for image processing.

In this example, GeoTagZ was able to match images with shutter events despite the receiver file covering a longer time period and so having more events than images.

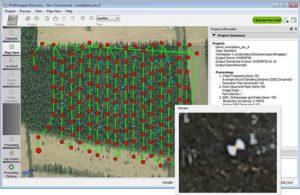

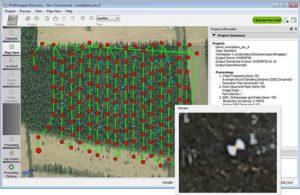

With the photographs now stamped with a precise time and location, they can be processed. The blue crosses in the screenshot below are the ground locations of check points used to determine the final precision and accuracy. They play no part in the processing.

This example details the use of Pix4D and PhotoScan however, other similar image processing tools could equally well have been used.

What accuracy can you expect on the ground?

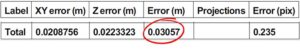

The photographs in this example were processed using two popular image processing software tools Pix4D and PhotoScan from Agisoft. The values highlighted below are the 3D-RMS values from their respective reports. These values are calculated from the sum of squared differences between each of the 20 check points’ surveyed positions and their positions as calculated using the image processing software.

The 3D accuracies for both software tools are better than 3.5 cm, with the height (Z) being the largest contributor to the total error. This is the same accuracy that a human surveyor would typically reach when surveying each of the 20 points check points manually.

Pix4D

Agisoft PhotoScan

GeoTagZ provides the missing link to centimeter-level ground mapping

The combination of high-resolution aerial photographs with GeoTagZ, for georeferencing with RTK positions from a compact high-end receiver module, provides the complete input for centimeter-level mapping precision on the ground. The same precision as manual survey can thus be achieved in a fraction of the time for all ground points within the surveyed area.

February 13, 2017 - Septentrio GNSS technology continues to provide solutions for challenging situations.

Case in point? The Belgian dredging, environmental and engineering group DEME. They rely on the accuracy and reliability of the AsteRx family of precise GNSS positioning solutions from Septentrio.

DEME is using Septentrio’s AsteRx GNSS receivers to obtain centimeter-level accuracy for all their dredging and marine construction operations worldwide.

These receivers are designed to operate in difficult conditions. From ice-covered Arctic ports to the tropical climates of Southeast Asia; whether dredging a few meters from the coast line to constructing wind turbines kilometers out at sea.

February 13, 2017 - Septentrio GNSS technology continues to provide solutions for challenging situations.

Case in point? The Belgian dredging, environmental and engineering group DEME. They rely on the accuracy and reliability of the AsteRx family of precise GNSS positioning solutions from Septentrio.

DEME is using Septentrio’s AsteRx GNSS receivers to obtain centimeter-level accuracy for all their dredging and marine construction operations worldwide.

These receivers are designed to operate in difficult conditions. From ice-covered Arctic ports to the tropical climates of Southeast Asia; whether dredging a few meters from the coast line to constructing wind turbines kilometers out at sea.

Your challenge, should you choose to accept it…

You’ve been asked to survey some points on the ground with centimeter-level accuracy. Feeling confident?

How about a few hundred points spread over 7.5 hectares (18.53 acres) and the job has to be done in one afternoon. Throw in the fact that the area you have to survey is in a quarry which has been closed off due to a recent landslide. Still feeling confident?

You should and here’s why.

Improvements in Unmanned Aerial Vehicle (UAV) technology combined with more compact high-end Global Navigation Satellite Systems (GNSS) receivers means that you no longer have to compromise on precision to measure in those hard-to-reach areas.

Your challenge, should you choose to accept it…

You’ve been asked to survey some points on the ground with centimeter-level accuracy. Feeling confident?

How about a few hundred points spread over 7.5 hectares (18.53 acres) and the job has to be done in one afternoon. Throw in the fact that the area you have to survey is in a quarry which has been closed off due to a recent landslide. Still feeling confident?

You should and here’s why.

Improvements in Unmanned Aerial Vehicle (UAV) technology combined with more compact high-end Global Navigation Satellite Systems (GNSS) receivers means that you no longer have to compromise on precision to measure in those hard-to-reach areas.

UAVs have become more reliable and easier to work with: from programming flight paths to installing additional equipment on board, UAV applications are no longer confined to a limited group of specialists.

For a survey flight, your UAV will need to have installed: a high-resolution camera and a high-end GNSS receiver module. To fly the UAV through a pre-programmed flight plan, an autopilot flight controller is often included.

UAVs have become more reliable and easier to work with: from programming flight paths to installing additional equipment on board, UAV applications are no longer confined to a limited group of specialists.

For a survey flight, your UAV will need to have installed: a high-resolution camera and a high-end GNSS receiver module. To fly the UAV through a pre-programmed flight plan, an autopilot flight controller is often included.