PV Solar Panel Field Inspection with UgCS Mission Planning Software

Solar panel fields, like any other artificial infrastructure objects, require periodical inspections. Usually photovoltaic (PV) solar panel field inspection requires use of two sensors – infrared (IR) and daylight cameras, to detect faulty panels. Solar panels may heat up because of connection issues, physical damage or debris.

Solar panel fields, like any other artificial infrastructure objects, require periodical inspections. Usually photovoltaic (PV) solar panel field inspection requires use of two sensors – infrared (IR) and daylight cameras, to detect faulty panels. Solar panels may heat up because of connection issues, physical damage or debris.

A drone equipped with a thermal camera is the best choice for solar panel field inspection. This method saves costs compared to manned aviation and saves time compared to visual control with handheld IR camera.

Semi-professional drones with changeable cameras like DJI Inspire are an option. However, switching out cameras means flight time is doubled. The first is a survey flight conducted with a daylight camera. The flight is then repeated after changing to an IR camera. To minimize time required for inspection usually both sensors (cameras) are used simultaneously. Such a payload requires a drone with enough lift-off capability.

Detectable defects

The two major defects visible with IR camera are connection issues and physical damage.

Connection issues occur, for example, when a panel or a string of panels are not connected to the system. As a result, power produced from the panel(s) cannot flow through the system and on to the grid. That power is converted to heat and the entire panel(s) will heat up slightly.

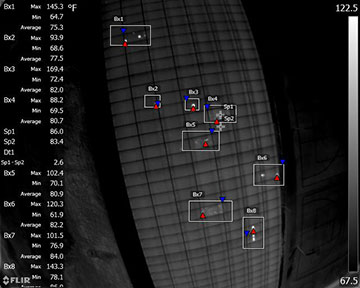

For example, (see Figure 1) the panel marked Bx7 presents little bit higher average temperature comparing to other panels and should be checked for both – defects and connection issues.

Another detectable defect is physical damage to the underlying panel. This causes small areas of more extreme heating as power flows around and backs up behind the damaged area.

Such defects are visible on sample – bright point in rectangle marked Bx3 with maximum temperature 169.4 F (76.3 C). Also, physical damages are visible in other zones.

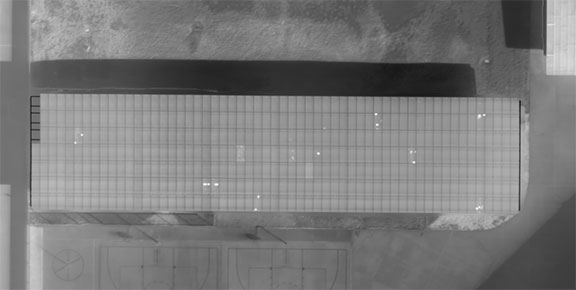

Both kind of defects usually are clearly visible on images in IR spectrum what makes defects localisation relatively easy even on stitched orthophoto.

In visible spectrum, (using daylight camera) usually only debris on panels is detected. This information, though, helps determine if the hotspot is the actual panel heating up or if it is the debris (dirt, bird droppings, etc) heating up.

Glass breaks are usually not detectable unless drone will fly very low as the cracks are small. Only in case of severe damage situations glass breaks will be visible on photos.

Solar Panel Field Inspection Mission Planning in UgCS

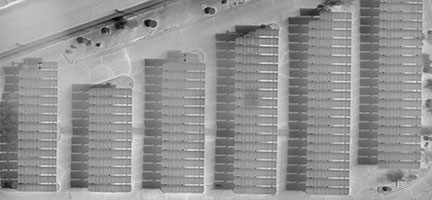

In general, solar panel field inspection missions with drones are planned the same way as standard UAV photogrammetry missions. The survey area is set and the route and camera settings are optimized to obtain the best result for data processing.

GSD selection

For photogrammetry, mission ground sampling distance (GSD) is defined by client and it is the main characteristic of survey’s output data.

In case of solar panel inspection client has to define which defects have to be detected. To detect panels with connection issues GSD for IR images should be set 25 cm. To detect physical damage or hotspots smaller than whole panel the GSD should be set from 5-16 cm.

For survey missions, when a drone carries IR and daylight cameras simultaneously, the GSD for daylight camera isn’t relevant. This is because it produces pictures with much better GSD than IR sensor because of the low resolution of thermal cameras. For example, an optical camera with a 16 mm lens to match the 7.5 mm FLIR lens will produce images with 1.3GSD while the FLIR images are at 15.7GSD.

For solar panel survey missions, when a drone with changeable cameras is used set GSD > 2 cm – this will enable to detect even small debris on panels but will not produce thousands of images from flight.

Camera position

Mostly camera are set to nadir position. In situations where a tracker system can’t be positioned at a set angle or for some fixed array sites – based on the time of the day and sun position oblique setup can be used.

Optimal angle of solar panels for thermal images is from 5 to 30 degrees to avoid reflection and inaccurate temperatures. If such images can’t be acquired with nadir camera position, the camera angle has to be adjusted to ensure pictures of panels in range from 5 to 30 degree angle.

Data processing

Standard image data processing techniques can be used to stitch photos taken with daylight and IR cameras.

Orthophoto maps of relatively small solar panel fields can be analysed manually with different zoom level. To enable rapid evaluation for large fields with millions of panels automated defect detection should be used. Defected panels are marked and further inspections can be accomplished manually.

Without doubt the use of UAV for area surveying or infrastructure inspection saves on both time and cost. Drone mission planning features and tools of UgCS enable UAV professionals to customize each mission according to application requirements.

Find the right UgCS Mission Planner Software that is right for you at Unmanned Systems Source.

Article is written in collaboration with Industrial Aerobotics, Arizona-based company providing aerial inspection, surveying and mapping services using UAVs and reprinted with permission.